|

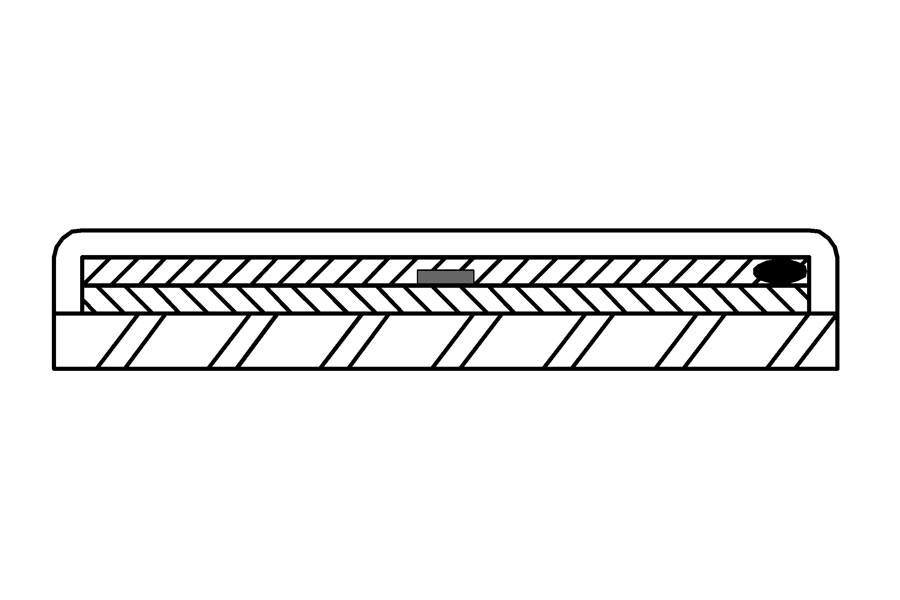

[pRFID-Inlays] is an acronym for passive radio-frequency identification inlays, currently used for the purposes of identifying and tracking objects that are attached for use within supply line allocations and warehousing redistribution; being an electronic device that comprises primarily a

chip, an antenna, both supported and connected on a

substrate; typically capable of carrying 3K bytes or more of included writeable memory.

cStar Technologies Inc., over the past years, has been occupied in distinct pRFID inventive research, development and diligence of build construction processes for our product line of ‘Stealth Tags’. Over those years

cStar has had the good fortune of being involved in the successful completion of various advanced progressive applications for these integrated ‘Stealth Tag’

systems, allowing cStar to shape a new approach in the decisive monitoring of intense fatigue caused by cyclic loading in many forms.

Stress Curve [S-N Mode]

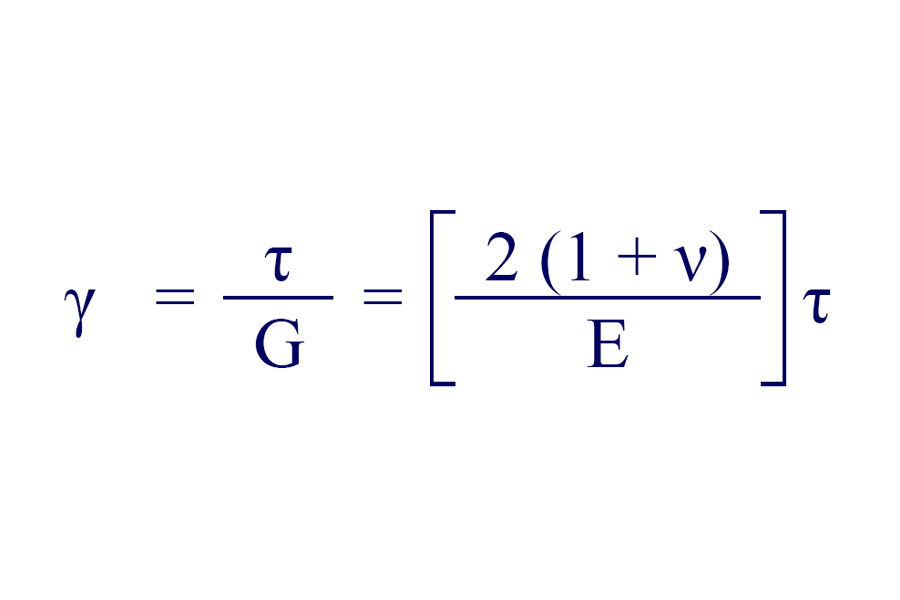

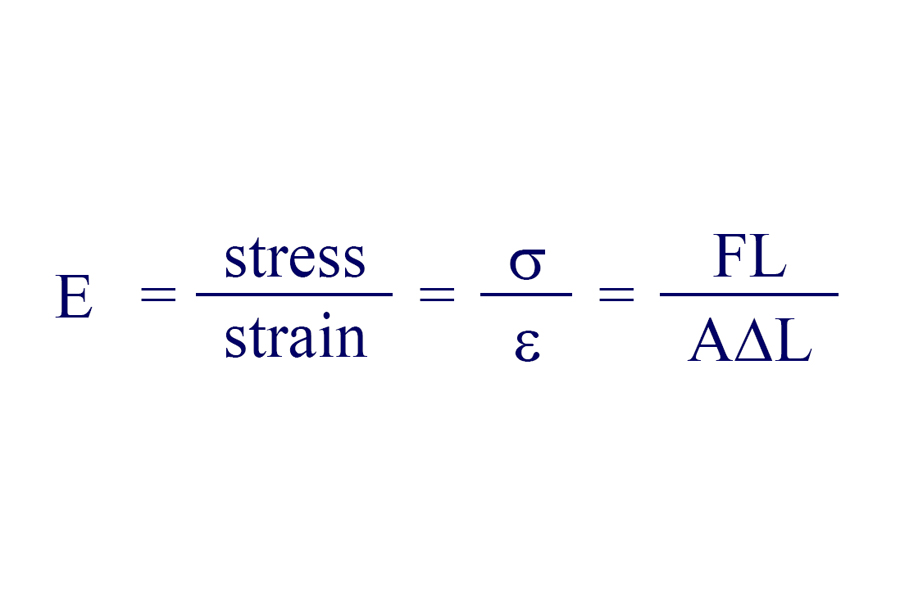

Generally, stress and strain as applied to shear,

longitudinal, or torsion even axially loading, are now

capable of being monitored in real-time for net stresses

in all these directions. Fatigue specifics follow S-N curve plots

that indicate the smallest prelude events towards failure as they

develop.

pRFID Tag Fuse or Diffuser

A fully integrated operating system, which meets existing fatigue detection necessities in the following

objectives:

Fatigue failure is defined as the tendency of a structured substance to fracture. Metallic [Steel, Alloy Steels, Alloys, Aluminum, Molybdenum, Titanium] and robust Plastic [Polyoxazole Matrix type Epoxies], disclose fatigue within these substances most often results from sequenced, localized fluctuation. This causes structural damage that occurs when a material is subjected to ‘cyclic loads’, resulting in failure at stress levels which are often less than the ‘ultimate tensile stress limit’; actually may also be below the ‘yield stress limit’ of these materials. These fatigue considerations are important because the consequent failure is gradual and at a stress level lower than strength values determined by their ‘Fatigue Index’ [Mechanical Metallurgy – Dieter]. As you will see – fatigue usually occurs from events materializing as surface break-off striations [slip-bands] meaning the solid is intensifying towards failure.

The significant advantage for using our pRFID devices within recognized places that are subject to repeat cyclic loads, in real-time, and online, 24/7 under operational conditions provides an immense protection advantage. Constructively, the

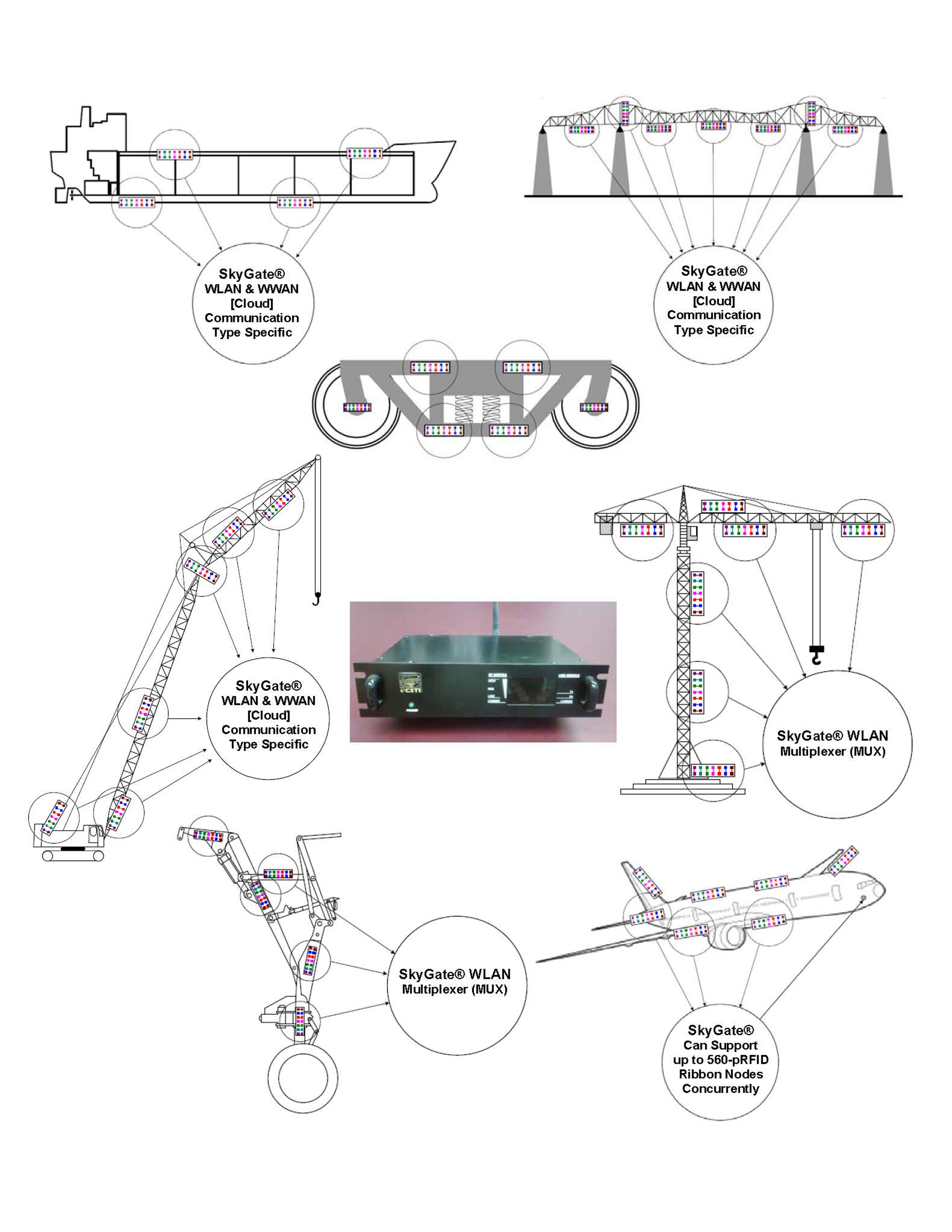

SkyGate® Reader’s ubiquitous frequency hopping spread spectrum resource allows the Ribbon-Strip Inlays to be positioned with a 600-feet pervasive envelope coverage area. When these Ribbon-Strips are placed throughout the chosen desired mapped zones they will respond to the resonating signature coded identifier scanning signal individually. In the event detuning occurs due to an antenna being shattered, caused by a fracture/fissure split; it is immediately detected once the Inlay can no longer resonate or respond to the polling signal; accordingly failure and location are immediately identified and located.

In this respect each individual graded Inlay element utilizes electromagnetic fields to receive and transfer TID unique integer-code identifier to the

SkyGate® Readers, using electronic recognized coded correlations. With cStar Technologies Inc., ‘know how’ we have turned this existing perception ‘on-its-head’ by using the Inlay’s antenna to detect fatigue failure when it is broken or shredded within various substances and objects subjected to repeat alternating and recurring cyclic loads. In structural substances fatigue deterioration is localized in regions exposed to these considerable cyclic loading patterns, including overload, combined stresses, metallurgical structure, wear-erosion, thermal stresses, and corrosion. Fracture cracks may take sometime to propagate, depending on both the intensity and frequency of burden, usually providing insignificant warning prior to failure and before any fatigue causing situations become apparent; in certain cases they are inconspicuous located and when in full view often invisible to the naked eye thus remaining unnoticed.

What "SkyGate®" Does

SkyGate® consists of a diversity of hardware, firmware and software elements, making available data collection, transmission, processing, storage and prearranged appearance objectives and is: A totally enclosed device, designed to perform a multiplicity of functions including data collection forwarding to a WLAN or WWAN or Cloud Networks.

Note: Electromagnetic waves travel at the same speed within the electromagnetic spectrum.

There are many different types of waves with varying frequencies and wavelengths.

They are all related by an important expression.

Electromagnetic Frequency ( λ )

multiplied by Wavelength ( ν ) equals the Speed of

Light ( c )

cStar offers a nondestructive evaluation typically shown, as influenced in the S-N curve representation where monitoring is shown as the method of providing structural health observation progressively as Inlay-Elements crumble. Fatigue in microstructures has become more prevalent leaning towards awareness of cyclic loading behavior in both tough metal alloys and polymeric compounds realizing intrinsic and extrinsic characteristics of crack formation in their earliest phases. cStar has modeled it’s development in producing the thinnest [in opposite surfaces] pRFID Inlays that facilitate the 'featherweight' and 'lightweight' phased events. Failures occur at the quasi-brittle state with crack propagation failure leading to the 'fatigue' phenomenon. Oftentimes at least 90% failures occur only after a considerable period of service frequently occurring below the design strength of the material and certainly unobservable; including deformation and fatigue roles of high-cycle and ultrahigh-cycle realms.

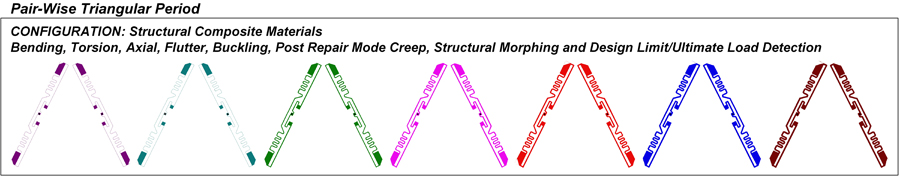

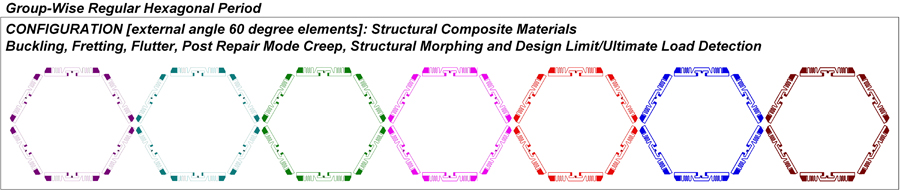

Special emphasis has been given in cStar’s pRFID Inlay development towards laminates under multi-axial, ply-level and bi-axial shear amplitude loading, as would also apply to fatigue behavior in welding and adhesive bonding joint configurations for detection of de-lamination crack propagation under cyclic loads.

By taking advantage of the extraordinary benefits in

using cStar's advanced pRFID compilation designs,

essentially behaving as a "fatigue fuse",

this Multi-Inlayed-Strip progressively shatters

proportional to the level of stress and strain imposed

upon it. The rise/run fatigue crack sequences, imparted

by extreme cyclic loading initiated from the substance's

merest early-on skin "slip-ring" effect, act

in unity on both the substance and inlay substrate. Significantly,

cStar's pRFID "Antennas" are

designed to receive and radiate electromagnetic waves

frequently energized by polling from a cStar SkyGate®

reader while the substrate bonded support remains

intact. Consequently, this fuse assembly

comprises an innovative adhesive bond-line backbone

resilient substrate imprinted with a uniquely

interval-etched conductive antenna connected to the IC.

These anomalous materials provide apposite compatibility

when affixed on to positions at locations prone to

yield-frailty regions.

Note: A Ribbon-Strip comprises a substrate bearing a plurality of radio frequency identification

Inlays, these different Inlays detune when responding to differing load intensities.

The Substrate Ribbons, application specific, may be ‘progressive strength breach’ continuous lognormal strip-type as shown, or alternatively individual segment type in various profiles or required contouring.

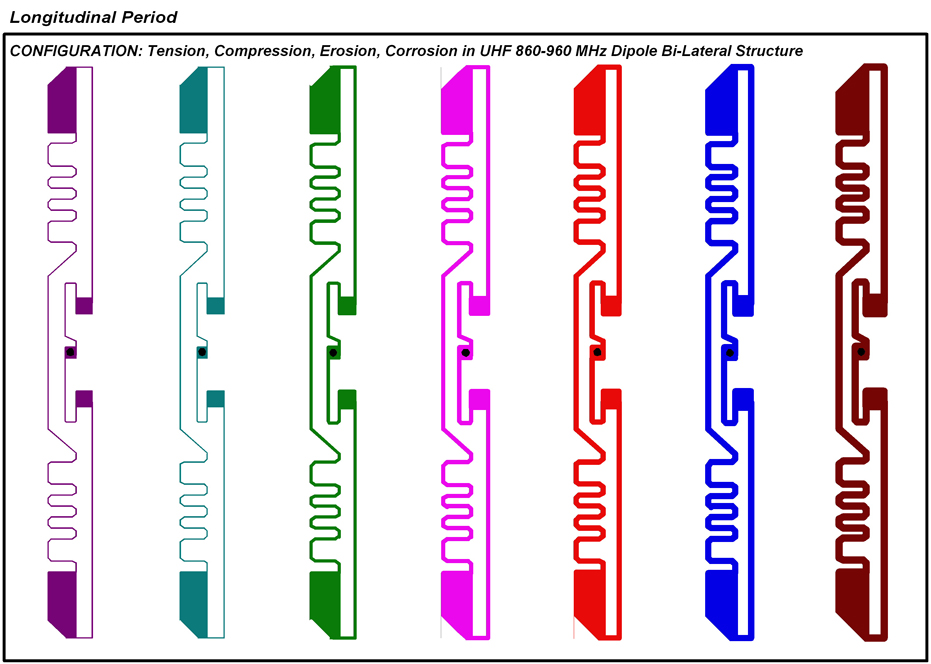

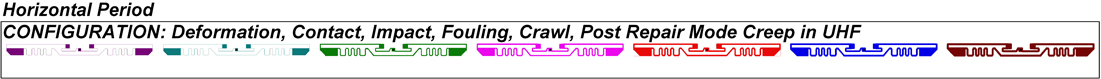

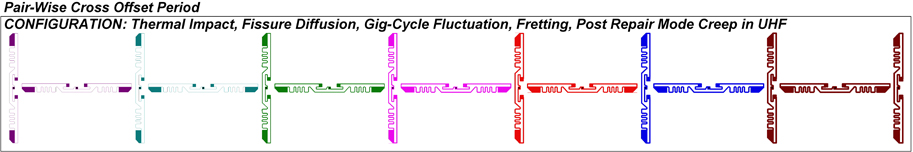

cStar's wireless frequency designs comply with FCC

operating equipment for ISM Bands Pt-15. cStar's antenna

configurations are appropriate for low frequency (LF)

[distinct form etched coil], high frequency (HF) [unique

contour coil etched design], ultra high frequency (UHF)

[novel dipole etched bilateral profile], and super high

frequency (SHF) [helix etching onto a sintered ceramic

array] frequency domains, each having peculiar and

innovative designed configurations that are application

specific. This makes cStar's pRFID FUSE an advanced

exceptional cost effective system, precluding the need

for ultra-expenses and all-embracing extensive wired

systems and associated equipment usually applied in a

required static or immobile languid state.

Tangible incident phases can occur in a

multi-functional environment depicted below, where

certain members of assorted structure, frames, and

exterior casings may be subjected to a combination of

external excessive load stresses, imposed during

uncharacteristic operations. These become principal

fatigue failures when exposed to tension, compression,

torsion, bending, and/or flutter conditions.

cStar's SkyGate® Fatigue Monitor

solution is protected by the following patents:

US Patent 7559482

Supplementary antenna for radio frequency identification and product containing unit incorporating same

US Patent 6563813

Wireless Transport Protocol

US Patent 6873620

Communications server including virtual gateway to perform protocol conversion and communication systems

incorporating the same

US Patent 8063779

Container including a tamper-resistant seal and radio frequency identification seal

US Patent 9070068 (A Continuation in Part {CIP} of US Patent #8,063,779)

Passive Tamper-Resistant Seal and Applications Therefor

US Patent 9483724 (Continuation in Part #2 of US Patent #8,063,779)

Passive Tamper-Resistant Seal and Applications Therefor

US Patent Application #15/286797 (20170024989)

(Continuation in Part #3 of US Patent #8,063,779)

Passive Tamper-Resistant Seal and Applications Therefor

US Patent 8145546

System and Method for Tracking Inventory

|